Valves Automation In Water, WTP And STP Plant Automation

We are Manufacturer, Supplier, Exporter of Valves Automation In Water, Water Treatment Plant Automation (WTP Plant Automation), Sewage Treatment Plant Automation (STP Plant Automation), Sugar Industry Automation, Pulp And Paper Industry Automation, Motorized Basis Weight Valves For Paper Industry, Motorized Glass Control Valves, Position Transmitter With Linkages. Our set up is situated in Pune, Maharashtra, India and we provide our products and services to ALL OVER THE WORLD.

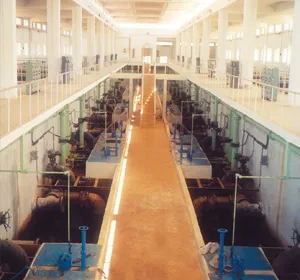

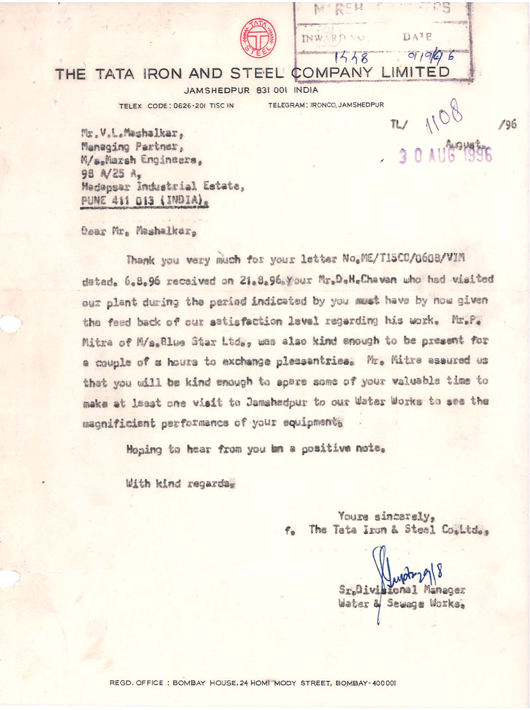

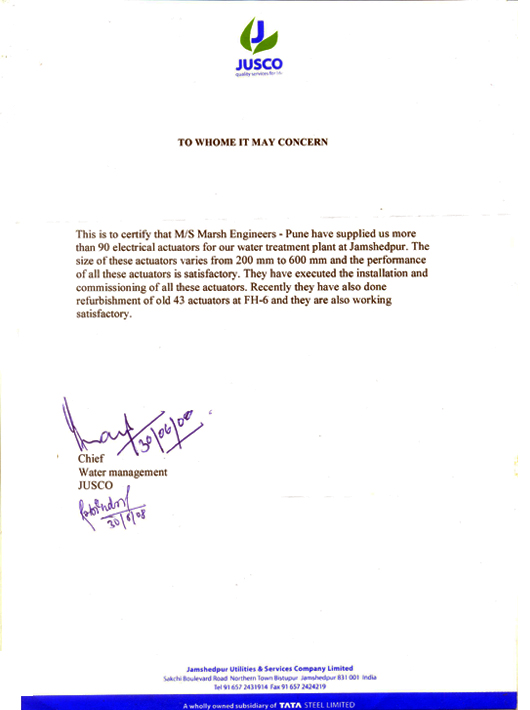

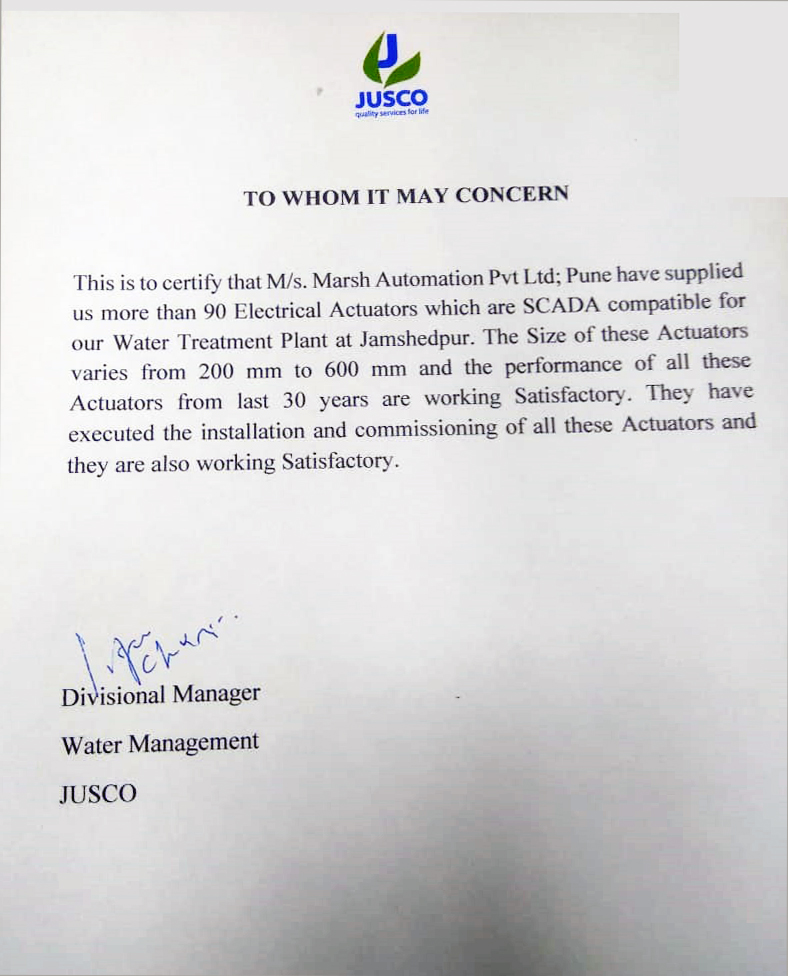

Marsh one of the Pioneers in Water Treatment Plant Automation in India. One of our earliest Plant Automation was for TATA Steel Water Treatment Plant now known as JUSCO.

Our founder Mr. V. L. Mashalkar had automated existing valves in 1980's.

Our units have been successfully working from 1984 till date. With changing times, the same have been modified to be SCADA compatible.

The below letters are testimony it to last 40 years of Automation.

Large size valve automation has been carried out by Marsh, its being more than 15 years that Marsh has automated ø 3000 mm valve at Pune Municipal Corporation Main raw water line we have provided with actuator, gear box, necessary bracket coupler & generator backup

• Some of our Major installation with: 100 + units

• Pimpri Chinchwad Municipal Corporation: 200 + units,

• Maharashtra Industrial Development Corporation: 600 + units

• Raipur smart city: 200 + units

• PHED Rajasthan - Sanchore: 920 units

• UP Jal Nigam – Allahabad: 380 nos

• UP Jal Nigam – Gorakhpur: 150 nos

• UP Jal Nigam – Lucknow: 300 nos

• MJP (Maharashtra Jeewan Pradhikaran) 500 + units

• Marsh is approved with almost all the major water boards in India and have automated few smart cities.

• Marsh has a dedicated team to automate valves from size 50-3000mm.

Attemperator Valve

Right Angle Valves

MARSH in the last 35 Years has automated.

Sugar Section

Baggase Gates

Right Angle Valves

Pan Discharge

Mud Gates

Steam Valves

Co-gen Plants

Attemperator Valve

Stop Valves

| Sr. No. | Customer | Application |

|---|---|---|

| 1 | The Dhampur Sugar | Motorized Steam Control Valves |

| 2 | Lipi Boilers | Motorized Damper for I.D., F.D. Fans |

| 3 | Krupp Industries | Motorized Damper for I.D., F.D. Fans |

| 4 | Walchandnagar Inds | Motorized Feed water Control Valve |

| 5 | Sevengalla (Sri-Lanka) | Motorized Damper for I.D., F.D. Fans |

| 6 | Ravalgaon Sugar | Motorized By-pass Valves, Position Transmitters, Actuator for Right Angle Valve |

| 7 | Datta. SSK-Shirol | Motorized Feed water Valves |

| 8 | Ugar Sugar Works Ltd | Automation of: Bagasse Feed Gates, Attemperator Control Valves, Turbine Header Valve, Main Steam Stop Valve, Steam Drain Valve |

| 9 | Kakatiya Sugar Jawahar SSK | Bagasse Feed control gates, Motorized Control Valves, ID / FD Fan Damper actuators |

| 10 | Bannari-Amman Sathyamangalam | Bagasse Feed control gates, Entire Mill & Pan Valve Automation |

| 11 | NCS Gayatri | Bagasse Feed Gates-Automation |

| 12 | Terna SSK | Bagasse Feed Gates-Automation |

| 13 | Madha SSK | Motorized High press Steam Valves |

| 14 | Jeypore Sugar –Chagallu | Automation of: Attemperator Control Valves, Main Steam Stop Valve |

| 15 | Bhima SSK | Motorized Ball Valves |

| 16 | Dnyaneshwar SSK | Motorized Butterfly Valves - Distillery |

| 17 | Godavari Sugar Sameerwadi | Entire Mill & Pan Valve Automation |

| 18 | Ghagare Sugar | Right Angle Valves –Automation |

| 19 | EID – Parry Nellikuppam | Entire Mill & Pan Valve Automation |

| 20 | Shri Renuka Sugars Ltd | Entire Mill & Pan Valve Automation |

| 21 | Bannari Amman Sugars Ltd | Pan Valve Automation |

| 22 | DCSL – Ajbapur/ Rupapur | Automation of: Turbine Header Valve, Main Steam Stop Valve, Pneumatic Pan Valve Panels, Steam Drain Valve, Entire Pan Valve Automation |

| 23 | Rajshree Sugars Ltd | Steam Inlet Vapor Outlet & Exhaust |

| 24 | Shri Pandurang S.S.K. | Motorized Steam Control Valves |

| 25 | Ganpati Sugar | Motorized Steam Control Valves |

| 26 | Shri Gurudatta Sugars Ltd | Motorized Steam Control Valves |

| 27 | Lanka Sugar (Sri Lanka) | Electrical Actuator |

| 28 | Gokak Sugars Ltd | Electrical Actuator |

| 29 | Rana Sugar -Pakistan | Vapor Valves/Pan Valves at Steam Recovery System |

| 30 | A B Sugars Limited | Fabricated Right-Angle Valves |

| 31 | Swaraj Green Power & Fuel Limited | Fabricated Gate Valve |

| 32 | Indian Sucrose Limited Mukerian | Fabricated Globe Valve |

| 33 | Shivshakti Sugar Limited | Vapor Valves/Pan Valves at Steam Recovery System |

| 34 | Vithal Sugar | Pan Valve Automation |

| 35 | Vishwaraj Sugar Industries Limited | Motorized Steam Control Valves |

| 36 | Balrampur Chini Mills ltd Haidergarh | Entire Mill & Pan Valve Automation |

| 37 | Siddeshwar Shahkari Sakhar Karkhana Ltd | Pan Valve Automation |

| 38 | Dewan Sugars Limited | Pan Valve BFV+ Pneumatic Actuator |

| 39 | Gokul Mauli Sugar Limited | Entire Mill & Pan Valve Automation |

| 40 | Chadda Sugar Mill Kiri Afghana | Electrical Actuator |

| 41 | Superior Food Gains Ltd -Unn Sugar | Fabricated Globe Valve |

| 42 | Babhnan Chini Mill UP | Electrical Actuator |

- V-notch contour offers an equal percentage characteristics for control.

- Valve sizes from 25 to 300 mm.

- Ideally suitable for throttling of fibrous pulp.

- Actuator movement 280 sec. /90° or 306 sec. /90°

- Standard pulse width 0.01 sec.

- 27400 or 30600 steps /90° - valve movement.

- Can be directly hooked to DCS or QCS systems.

- Valve positioner to accept 4-20 mA or 0-10VDC signal from controller.

- Feedback potentiometer to give ohms output.

- Electronic position transmitter to give an output signal of 4-20mA.

- Digital Valve Position indicator.

- Open / Close push buttons for manual operation.

- Auto / Manual Selector switch.

| Valve Type | V-notch / Segment Ball Valve |

| Size | DN - 25 40 50 75 100 150 200 250 & 300 |

| End Connections | Flange less / Flanged - Optional |

| Leakage Class | Metal to Metal Seated - ANSI Class IV Soft Seated - Teflon - ANSI Class VI |

| Body rating | ANSI 150 and ANSI 300 |

| Characteristics | Equal Percentage - Approx. |

| Body | 316 SS / Carbon Steel / Titanium |

| Ball / Segment | 317 SS / Hard chrome plated Steel |

| Seat | 316 SS / Teflon |

| Packing | Teflon - V - rings / PTFE |

| Description | Specification | |

| Models | ST - 5102 - S | ST 5103 - S |

| To suit Valves - Size DN | 25 40 50 75 & 100 | 150 200 250 & 300 |

| Operation time Sec/90° | 280 | 306 |

| Torque developed - Nm | 150 | 375 |

| Degree of Protection | IP - 55 | |

| Switching frequency- Operations / hour |

7000 |

|

| Standard pulse width | 0.01 sec. | |

| Resolution steps /90° | 27400 | 30600 |

| Input Signal | 230 /110 V AC Pulses from DCS / QCS OR 4-20 mA / 0-10 VDC Control Signal from Controller |

|

| Motor Type | Non blocking - Stall Duty A. C. Motor | |

| Supply Voltage | 220/110 VAC 50 / 60 Hz 1 Phase | |

| Motor rating - watts | 4.7 | 23.6 |

| Class of Insulation | F | F |

- Travel limit switches : 2 Nos. (1 NO + 1NC)

- Hand wheel for manual operation.

- Local position indicator

- Additional limit switches 2 Nos. ( 1 NO + 1NC)

- Feedback potentiometer

- Two / Four wire transmitter

- Remote position indicator - digital Control panel

- Positioner to accept 4-20 mA / 0-10VDC

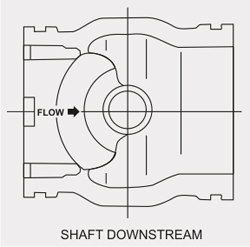

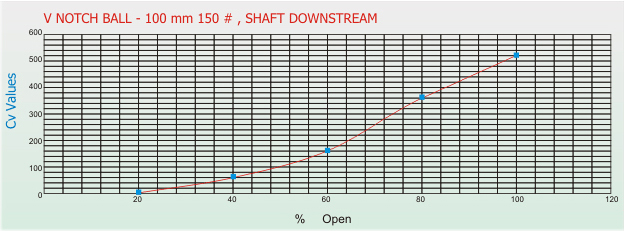

Shear Stream

Class 150-600

Shaft down stream

| Valve Size DN |

Cv at degrees open | ||||||||

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | |

| 25 | 0.1 | 0.72 | 1.8 | 3.5 | 5.7 | 8.6 | 12.4 | 75.6 | 24 |

| 40 | 0.21 | 1.4 | 3.7 | 7.4 | 12.3 | 18.9 | 28 | 40 | 57 |

| 50 | 0.5 | 3.2 | 7.2 | 13.2 | 21 | 32 | 47 | 70 | 110 |

| 75 | 7 | 19 | 34 | 56 | 85 | 124 | 185 | 239 | 280 |

| 100 | 13 | 33 | 59 | 94 | 140 | 195 | 271 | 361 | 462 |

| 150 | 19 | 54 | 110 | 176 | 260 | 371 | 519 | 716 | 945 |

| 200 | 45 | 104 | 185 | 291 | 425 | 589 | 825 | 1172 | 1675 |

| 250 | 92 | 220 | 354 | 572 | 835 | 1150 | 1620 | 2250 | 3180 |

| 300 | 120 | 287 | 461 | 746 | 1090 | 1500 | 2120 | 2940 | 4150 |

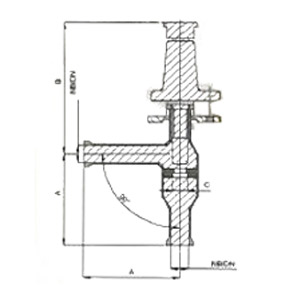

The Package Mainly Consists of

- Glass Valve

- High Resolution Electrical Actuator

- Accessories

Brief Description

Waste from pickling process which mainly consists of Hydrochloric Acid, Suspended Iron Particles & Water along with CNG & Air is feed to a reactor in controlled manner through motorized Glass Valve.This acid gets converted to gaseous form in the reactor which is again converted to acid in an absorption column.

The Glass valve is made of Borosilicate glass and PTFE plugs. Glass valve allows visual checking to monitor flow of acid and see that crystallization does not take place. The valve has to be washed periodically with water to remove iron particles if any.

| Valve Size in NB | 25. 40.50 |

| End Connections | Flanged |

| Material | BorosIkate Glass |

| Plug | PTFE |

| Max. Temperature | 200° C. |

| Media | Hydrochloric Acid |

| Valve Types | Straight Through Valves, Drain Valves, Angle Valves, Vent / Vacuum Valves, Bottom Outlet Valves etc. |

| Valve Ref. No. | NB/DN | A | B | C |

| RP 1 | 25 | 100 | 175 | 18 |

| RP 1.5 | 40 | 150 | 200 | 26 |

| RP 2 | 50 | 150 | 220 | 38 |

| Description | Specification of an Electrical Activator | Standard Accessories |

| Model | ST 5102 - G | 1. Trawel Limit Switches |

| Glass Valve - Size NB | 25, 40, 50 | 1NO + 1NC - 2 Nos. |

| Operation Time in Sec. | 18-20 Approx | 2. Hand Wheel for manual operation |

| Linear Speed mm/sec | 0.26 / 0.52 | |

| Rated Thrust Kg's | 200 | 3. Local Position Indicator |

| Medium Cleaning Thrust in Kg's | 350 | |

| Degree of Protection | IP - 55/65 | Optional Accessories |

| Switching Frequency Short Time / Normal | 7000/1800 | Auxiliary Switches |

| Input Signal | 4-20 mA, 230/110 VAC relay signal | Space Heater |

| Motor Type | Non Blocking - Step Synchronous Motor | Feedback Potentiometer |

| Supply Voltage V AC | 220/110 | 2/4 Wire Position Transmitter |

| Frequency | 50 Hz | Digital Indicator |

| Motor Rating - Walts | 4.7 | Panel Mounted Position to Accept 4-20mA / 0-10 V DC |

| Class of Insulation | F |

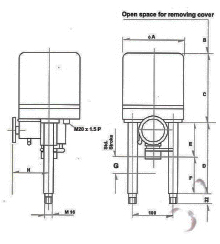

| Model | Dimensions | |||||||

| A | B | C | D | E | F | G | H | |

| ST-5102-G | 150 | 120 | 162 | 200 | 98 | 102 | 40 | 90 |

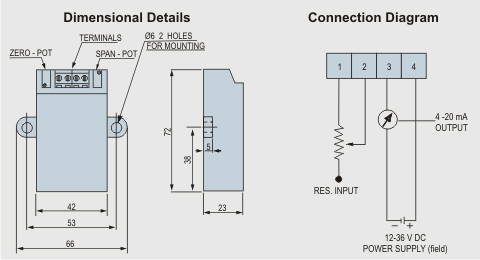

The two wire transmitter model PPT 200 is an electronic instrument to convert resistance input to current output. The change in resistance derived from the field mounted potentiometer is given as an input to this instrument through two wires. A supply of 12 to 36 V DC is connected to the output terminals of the instrument. As the input resistance varies the current signal of 4-20 mA is generated in the supply wires which can be read by connecting an ammeter in series with the supply wires as shown in the connection diagram. The Zero and Span Setting potmeters are provided on this instrument by which accurate output values of 4 and 20 mA can be achieved.

- Two wire Transmitter

- Uses state of art analog technology

- Accepts wide supply voltage variations

- Protection against reverse supply connections

- Epoxy potting ensures excellent - protection against dust, moisture etc.

- Customer setting - SPAN, ZERO -

- easily accessible.

- Note : SPAN and ZERO are interdependent

- Supply : 12 to 36 V DC

- Input : 100 to 235 - Standard supply. Other values available on demand (Only two wires of potmeter to be used as input)

- Output : 4 to 20 mA DC

- Customer : Zero : 4mA Span : 20 mA

- Linearity : ±1%

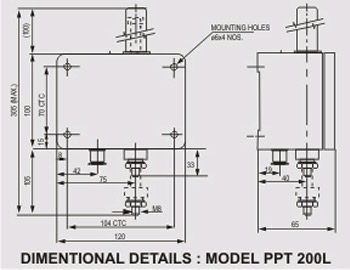

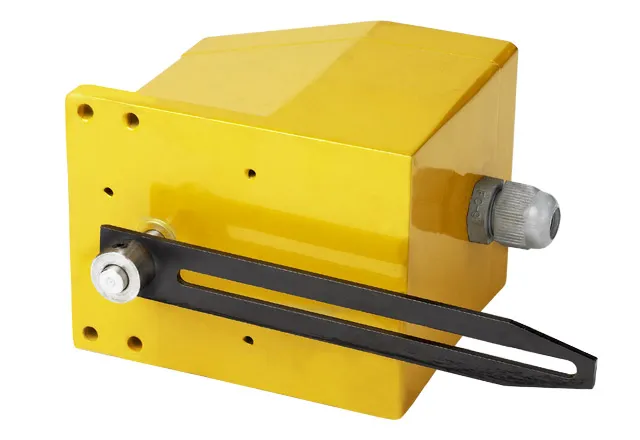

This model has a reciprocating shaft, which can be coupled to any linear moving part so as to convert linear mechanical movement into an out put of 4-20 mA proportionately.

The reciprocating shaft is coupled to the potentiometer and the potentiometer output is converted into 4-20mA thru position transmitter. All the items are housed in a box having proper sealing to make it weather proof. A suitable cable gland is provided for cable entry. Adjustable mechanical stoppers are provided on the reciprocating shaft to restrict the desired movement of the shaft.

This model has a reciprocating shaft, which can be coupled to any linear moving part so as to convert linear mechanical movement into an out put of 4-20 mA proportionately.

The reciprocating shaft is coupled to the potentiometer and the potentiometer output is converted into 4-20mA thru position transmitter. All the items are housed in a box having proper sealing to make it weather proof. A suitable cable gland is provided for cable entry. Adjustable mechanical stoppers are provided on the reciprocating shaft to restrict the desired movement of the shaft.

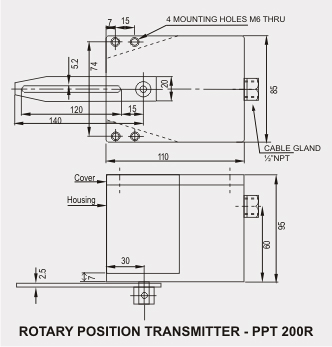

All Features same as that of PPT-200L Except that the External lever has a rotary action instead of reciprocating.

All Features same as that of PPT-200S except that switching operation will be thru rotary lever instead of reciprocating.

MARSH offers Electric Actuators for high pressure Globe & Gate Valves for ON / OFF and Regulating duty applications. They can be mounted directly on valves or the motion can be transmitted thru linkages depending on site conditions. The actuators are available with 230 / 110 VAC V AC 1 Phase or 415 V AC 3 phase motors to suit various valve sizes and operating pressures. The required standard and optional accessories are available to meet the specific process requirements. The service back up is also available for commissioning, to over-come initial troubles, and also to calibrate the unit with DCS / QCS compatibility.

| 1 | Item | Single / Three Phase Electric Actuator |

| 2 | Application | High pressure Linear / multiturn Globe & Gate Valves |

| 3 | Make | MARSH |

| 4 | ACTUATOR DETAIL (With std. Accessories) | |

| 4.1 Type | Regeltek / Emtork | |

| 4.2 Model | ST 5102/03, MT5, M0/M1-SG | |

| 4.3 Out put motion | Linear / Rotary | |

| 4.4 Rated out put Thrust / Torque | 200/600 Kg. 5/8 20 to 200 Kgm. | |

| 4.5 Out put speed | 0.26 to 0.8 mm / Sec and 1 to 365 RPM. | |

| 4.6 Out put coupling | A/C/D/E /special | |

| 4.7 Manual over - ride | Provided. | |

| 4.8 Travel limit switches | Standard - 1 NO + 1NC - 2 Nos Optional - 2 NO + 2NC - 2 Nos |

|

| 4.9 Torque limit switches | Standard - 1NO + 1NC - 2 Nos -- Only for 3 phase models Optional - 2 NO + 2NC - 2 Nos |

|

| 4.10 Local Position indicator | Provided | |

| 4.11 Class of protection | IP 65 - weather proof | |

| 4.12 Duty | ON - OFF / Regulating | |

| 4.13 Area of operation | Safe / optional - Hazardous | |

| 5 | 5.1 Type | Actuator duty |

| 5.2 Supply | 230/110 VAC - 1 phase 50 / 60 Hz 415/380 VAC - 3 phase 50 / 60 Hz |

|

| 5.3 Duty | ON / OFF - S1 Regulating -S4 |

|

| 5.4 Insulation Class | F | |

| 5.5 Rating | 5/24 watts, 0.37 to 2.2 KW | |

| 6 | OPTIONAL ACCESSORIES | |

| 6.1 Feedback potentiometer | Resistance / Inductive | |

| 6.2 Feedback transmitter | Two wire type - Model PPT 200 | |

| 6.3 Source for transmitter | Converter - 230 VAC to 24 VDC | |

| 6.4 Remote position indicator | Digital | |

| 6.5 Positioner | Actuator / Panel mounted - To operate the actuator with Input signal of 4-20 mA OR 0-10 VDC | |

| 6.6 Thermostat | In - built in motor winding / External | |

| 6.7 Control Panel | Local / Remote operation |