Our Complete Range of Electrical Actuators

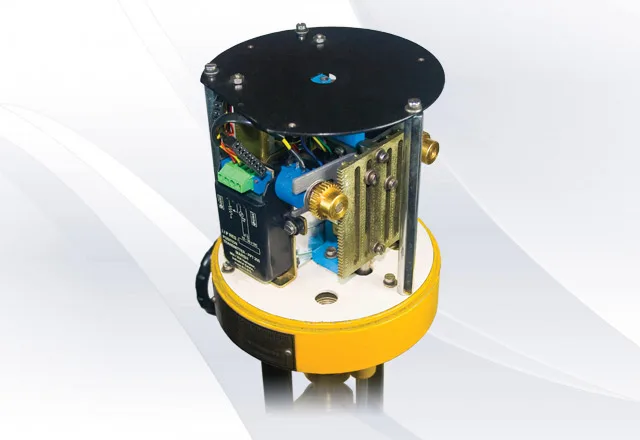

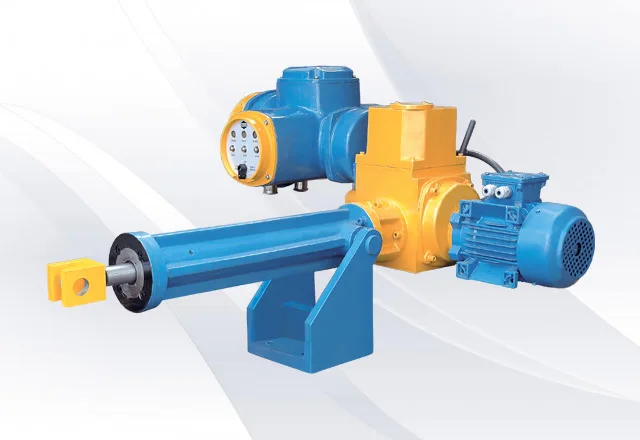

We are Manufacturer, Supplier, Exporter of Electrical Actuator, Emtork Electric Actuator, Linear Electric Actuator, Electrical Linear Actuator, Quarter-Turn Electric Actuators, Emtork Electric Thrusters, Actuator Accessories, Electronic Valve Positioners. Our set up is situated in Pune, Maharashtra, India and we provide our products and services to ALL OVER THE WORLD.

Our Complete Range of Electrical Actuators

As a leading Indian manufacturer since 1980, Marsh Automation Pvt. Ltd. specializes in precision flow control solutions. Our electrical actuators are the essential link between your control system and the final control element, delivering reliable, accurate, and powerful operation for valves, dampers, and gates across all industries.

In modern fluid and gas control, the transition from manual to automated operation is non-negotiable. Our robust electric actuators eliminate human error, increase operational efficiency, and provide crucial remote control and monitoring capabilities. Whether you require a high-torque unit for large pipelines or a fast-acting device for critical process control, Marsh Automation offers a comprehensive, expertly engineered range of multi-turn, quarter-turn, and linear electrical actuator solutions built to international standards.

1. Why Choose Marsh Electrical Actuators?

-

Unmatched Reliability: Our actuators, including the flagship Emtork Multi-Turn Actuators,

are engineered for continuous, heavy-duty service (S1 Duty).

They feature high starting torque motors and robust reduction gear units, ensuring flawless operation

in demanding industrial environments and minimizing downtime.

-

Precision and Control: Models are available for both On/Off (Isolating) and

Modulating/Regulating duty.

Our modulating actuators use precise positioners to accept a 4-20mA control signal,

accurately positioning the final control element to within 0.1% accuracy - essential for fine-tuning complex processes.

-

Cost Efficiency & Integration: Optional Integral Starter Panels reduce installation costs

by minimizing external cabling and simplifying wiring.

All units are easily retrofittable onto existing manual valves, enabling a seamless and cost-effective transition to automation.

-

Comprehensive Local Support: Based in Pune, Maharashtra,

we offer site support, maintenance services, and spare parts availability.

Our local presence ensures faster response times compared to international suppliers.

- Versatile Design: Each actuator is highly customizable with a range of output couplings, supplementary gearboxes (Spur, Worm, Bevel), and attachments suited for valves and dampers such as Globe, Ball, Butterfly, and Sluice Gates.

2. Types of Electrical Actuators Explained

Selecting the correct mechanical action is the first step in automation. Marsh Automation manufactures three primary types of electrical actuators to meet every industrial requirement.

| Actuator Type | Marsh Product Line | Motion Output | Typical Application | Key Function |

| Multi-Turn Actuator | Emtork | Rotary (Rotates > 360°) | Gate, Globe, Sluice Valves | Opening/Closing valves that require multiple stem rotations. |

| Quarter-Turn Actuator | QT Series (via Worm Gearbox) | Rotary (Rotates 90°) | Ball, Butterfly, Plug Valves, Dampers | Fast, $90^\circ$ actuation for isolating or regulating flow. |

| Linear Actuator | Regeltek & Thruster | Linear (Push/Pull) | Globe, Diaphragm Valves | Applying thrust to move a valve stem in a straight line. |

Focus on Motion

-

Rotary Actuators: Our Emtork Multi-Turn units are the workhorses,

providing the high-torque output necessary for large wedge-gate valves.

For 90° applications, we integrate supplementary worm gearboxes with our rotary units

to achieve precise quarter-turn motion.

- Linear Actuators: The Regeltek and Thruster lines are ideal for proportional control where a pushing or pulling force is required, offering smooth, reliable positioning for control valves.

3. Choosing the Right Electrical Actuator for Your Application

Choosing the perfect electric actuator involves a calculated review of process requirements. Follow these steps to narrow down your selection:

-

Determine Torque/Thrust:

This is the most critical factor. Calculate the maximum torque required to operate the valve or damper under the highest pressure or differential conditions. Our technical specifications clearly list the adjustable torque range for each Emtork model (e.g., M30 to M1000). Never select an actuator based solely on valve size. -

Define Duty Cycle:

- Isolating (On/Off): For valves that are infrequently operated (e.g., fully open or closed). S1 duty (continuous) is preferred for maximum longevity.

- Regulating (Modulating): For valves that adjust position frequently to maintain a set point. These require fast-acting motors and electronic positioning capabilities.

-

Specify Power Source:

Standard units operate on 415 VAC, 3-phase supply, but we also offer flexibility to meet other voltage requirements.

-

Confirm Mechanical Interface:

Ensure the actuator base flange and output coupling are compatible with your valve mounting - standardized to ISO or DIN specifications.

-

Environmental Conditions:

Consider the ambient temperature and the required level of protection - including Ingress Protection (IP Rating) and Explosion Proofing for hazardous areas.

4. Electrical Actuator Standards and Certifications (IP, ATEX)

Compliance with international standards is vital for safety, quality, and operational peace of mind. Marsh Automation is committed to manufacturing electrical actuators that meet and often exceed regulatory requirements.

Ingress Protection (IP Rating)

Our actuators are available with a high level of Ingress Protection against dust and water, certified as per IS-4691 and IS-2147:

- IP65: Protection against dust ingress and low-pressure water jets from any direction.

- IP67: Protection against dust ingress and temporary immersion in water (up to 1 meter for 30 minutes).

- IP68: The highest level of protection, suitable for continuous submersion - ensuring operation in flooded pits or severe weather.

Hazardous Area Operation

For industries dealing with flammable gases or dust (e.g., Oil & Gas, Chemicals), we offer flameproof and explosion-proof models designed and certified to prevent ignition of external explosive atmospheres.

- Flameproof/Explosion Proof Units: Our actuators are certified as per national and international directives, including ATEX (EU) and relevant Indian Standards, ensuring safe operation in Zone 1 and Zone 2 hazardous areas.

By prioritizing these technical and certification factors, you ensure that the electrical actuator you select from Marsh Automation will be a secure, long-lasting investment.